A Chance to Revive Railway Manufacturing in Hungary

What basic lines of business does HungaRail pursue?

– We are active, first of all, in design and consulting regarding the reconstruction of railways, as well as in drafting plans for – new and reconstructed – energy supply to electric traction at different levels (design, licensing, tendering and construction). Related to this, our portfolio covers the electric heating of points, commissioning and planning the operation of 25/0.4 kV column transformer stations and electric coach pre-heating plants, designing outdoor lighting, implementing remote control for overhead networks (local remote control equipment, OH energy remote control) and diagrammatic design of optical fibre OH lines. Moreover, we also procure parts for traction units and trailers (including safety glass, parts for diesel engines, wheel set parts, etc.) and participate as foremen representing the designer in the construction of facilities built according to construction plans prepared by HungaRail.

Which projects lent the company true momentum?

– In 1996, we evaluated a study on installing a heating oil storage facility for the Hungarian Power Company (MVM) near Záhony. Two years later we prepared decision support documentation for the procurement of two-current electric locomotives for GYSEV. In the early 2000s, we were commissioned by Bombardier to write a technical, traffic and economic study of the options to use the new electric trains in carriage, in the matter of traffic around cities and maintaining of vehicles.

It took us almost two years to design a new base at the old, ruined maintenance site at Pusztaszabolcs Station for 30 new electric motor-coach trains (supplied by Stadler). This project involved general design of the technological process of vehicle maintenance, the network of electric traction, electric heating for points and outdoor lighting. An OH network (our design) was also installed in the washing hall with 25 kV feed to move vehicles during the pre-wash operation.

Which has been HungaRail’s most interesting assignment in the past 18 years?

– We have prepared a technical and economic analysis of business opportunities in the segment of vehicle and traction engines in cooperation with traffic and industrial consultants for Transelektro Co. In addition to identifying the break-out points in these areas for the upcoming decade, the study also offered an alternative for the revival of railway manufacturing in Hungary. In the event the recommendations of that thesis had been accepted, I think the companies in the business of manufacturing vehicles for railway application would not have gone bankrupt.

Do you see any break-out points and future opportunities?

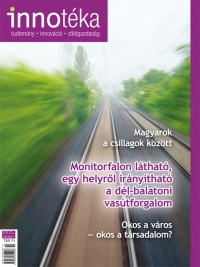

– Although the percentage share of carriage by rail had dropped from 6% to 4% in passenger transport by the early years of this millennium – with the share of rail in freight falling back from 16% to 9% in the past decade –, transport volumes have increased in both segments in absolute terms. Moreover, the attempts to further globalisation in rail transport demand swift and smooth cross-border movement. In the developed European economies there is a rapidly growing tendency to regionalise local railway lines with more limited traffic, and in the meantime, former locomotive-type operations are being replaced almost exclusively by motor coach solutions along main lines, with particular emphasis on high capacity, highly comfortable “double-decker” motor coach trains operated economically along suburban lines.

Electrification of a GYESEV line at Körmend Station

Electrification of a GYESEV line at Körmend StationIn our view, performing the major overhaul and refurbishment of passenger carriages would have been a break-out point: the full replacement of equipment used in passenger traffic and the reconstruction of heating and control, i.e. of the whole electric system. In recent years, 500-600 suburban and traditional long distance carriages should have been fully refurbished using the local capacity that existed and still exists in Hungary.

Developing railway signalling and interlock equipment would have also provided significant opportunities for advancement. Around the millennium, no considerable investments into station or line based interlock systems, oriented toward development or scrap replacement, were in progress along the lines operated by MÁV, except for a tender invited for the cross-over from Hungary to Slovenia, whilst GYSEV intended to spend HUF 1 billion on the same purpose. In 2001, MÁV’s network included 84,000 points and switches. These should have been connected to modern interlocking equipment whose manufacturing and installation costs would have amounted to quite a few hundred billion forints at prices then current. Judging by the dynamism and the opportunities of railways, this would have meant HUF 10-12 billion on an annual basis for Hungarian manufacturing. Additionally, there were 46 stations and junctions on MÁV’s territory, 85 percent of which is located along international railway corridors and main lines, where one cannot avoid but install new signalling and interlocking equipment. This area showed progress after EU funding had been provided, about a decade ago, for developing the Hungarian sections of European railway corridors.

We also have to be aware that the transport sector is the biggest polluter of our environment, and any development of the sector should therefore consider environmental goals as well as the benefits and external costs associated with each means of transport. Furthermore, as a member state of the EU, we need to ensure mobility, set as a goal by the European Community. Accordingly, future developments of the transport sector are inconceivable without railways.

Maintenance base for electric motor coach trains in Pusztaszabolcs

Maintenance base for electric motor coach trains in PusztaszabolcsWhat other bad decisions have you come across concerning MÁV?

– Dissecting the Hungarian State Railways was more than a grave mistake. The ballooning of administration was an outright sin. When I was appointed general manager in 1990, 860 people worked at the head office from Andrássy Street; four years later the headcount was 540. I’d like to stress that the reduced headcount did not come as a result of across the board layoffs, it was achieved by reorganisation. Nobody was dismissed; people were simply transferred to locations where extra hands were needed.

At present fifteen hundred employees work at the General Directorate in the leased crystal palace on Könyves Kálmán Boulevard, and I’m pretty certain that quite a few of them do not have even the faintest idea about life along the rails. You have to go out and meet people along the rails: that is what guided me as a principle all my life! Even as a general manager I regularly asked the highly skilled staff of operations to express an opinion as they are ‘professors’ of their own area and no school can teach you what they have learnt by spending decades on the spot.

What roles could hundreds of people be reassigned to now?

– I agree with Ilona Dávid, CEO, who said in an interview to the Hungarian daily Magyar Nemzet that there are plans for hiring on-board stewards to ensure the safety of conductors and passengers. I have pressed for that myself and have personally experienced the benefits of it in Austria and Switzerland. This innovative solution would serve to improve the quality of service. During the journey, stewards can pay attention to passengers’ mood, to the quality of service, in case of sickness they are able to give assistance to passengers. As members of this crew maintain telephone contact with train dispatchers, they can inform passengers about the delays in case of accidents or track obstruction. You can hardly imagine how important is the sense of safety for passengers and how much easier it would be for them to tolerate having to wait. Nonetheless, they could also assist conductors who have countless responsibilities at present. Let me give you just one example: conductors are responsible for checking that all doors are closed after each stop the train makes. Practical observations suggest that 50 percent of the passengers do not close the door. A single conductor has to check this 20-25 times between two terminals.

Does it really take so little?

– A passenger is certainly not interested in the model or the performance of the locomotive pulling the carriages. What really counts is train frequency, good timetable, timeliness, a sense of comfort, as well as appropriate and polite service. The introduction of a steward system would provide effective help in the latter area. Still, it would be worth trying even just to offer passengers a pleasant surprise. It has been really a long time since we surprised passengers by a unique development of this nature. It is worth trying!•